Kurt, if you're asking that SW shows tolerance for each dimension according to 2768 then you're missing the point of 2768. These two standards, ISO 2768-1 and ISO 2768-2 are general tolerancing specifications so you don't have to show dimensions on your drawings. General tolerances on perpendicularity Unit: mm Perpendicularity tolerances for ranges of nominal lengths of the shorter side Tolerance class Up to 100 Over 100.

ISO 2768-1:1989This standard was last reviewed and confirmed in 2017. Therefore this version remains current.

Abstract Preview

This part is intended to simplify drawing indications and specifies general tolerances in four tolerance classes. It applies to the dimensions of workpieces that are produced by metal removal or are formed from sheet metal. It contains three tables and an informative annex with regard to concepts behind general tolerancing of dimensions.

General information

- Publication date : 1989-11

- Number of pages : 3

- :Dimensional and geometrical product specifications and verification

- ICS :

- Limits and fits

Buy this standard

- CHF38

Life cycle

A standard is reviewed every 5 years

- 20

- 30

- 40Enquiry

- 50

- 60Publication

- 90.93Review

Revisions / Corrigenda

- Previously

ISO 2768:1973 - Now confirmed

ISO 2768-1:1989

Opening hours:

Monday to Friday - 09:00-12:00, 14:00-17:00 (UTC+1)

Keep up to date with ISO

Sign up to our newsletter for the latest news, views and product information

- Forum Actions

- Quick Links

Thread Tools

Display

- CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

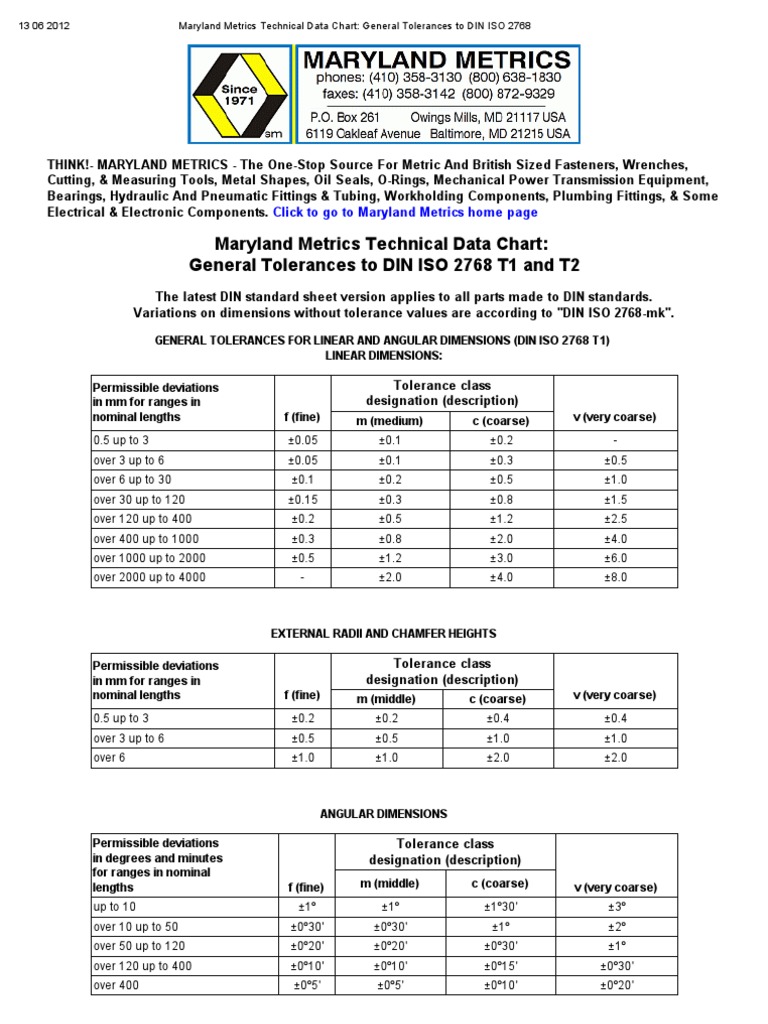

DIN ISO 2768 mk tolerances

I have some drawings from Germany that use the DIN 2768 tolerances and I am having trouble understanding it correctly. I do not have a full copy of the DIN but I do have some notes and a brief discription of how the tolerances are supposed to work but I still dont quite understand it.

The parts are shafts and couplings and have to fit bearings so I know some of the tolerances are going to be plus and some are minus. Could anyone offer a simpler explaination of what I am seeing.

One of the external shafts has a f9 while most of the other shafts have a h9 or h6. A keyway has a N9 and the internal keyway has a j59. One of the internal bores has a M6. Most of the tolerances use lower case but some are upper case, I dont know if that makes a difference or not.

Anyone know of a source for a simpler explaination of these that is in english?

Charles - Mark McGrathDiamond

- Join Date

- Mar 2002

- Location

- Scotland

- Posts

- 4,232

- Post Thanks / Like

- Likes (Given)

- 1019

- Likes (Received)

- 472

The internal bore with M6 sounds like it`s threaded M6 x 1.0 pitch.

Are the other tolerances not in Machinery Handbook? - Hot Rolled

- Join Date

- Sep 2002

- Location

- New Milford, CT

- Posts

- 565

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 4

A bearing catalog will have a table with the tolerances. You can also find everything you should need here at this link

http://medias.ina.de/medias/en!hp.tg.cat/tg_rot*CQNXFU

Basically, a small letter is the tolerance for a shaft and a captial letter is the tolerance for the hole. The M6 is the tolerance for that bore and is not a thread designation. The tables write the tolerance in micrometers, or the number given / 1000 is the tolerance in mm.Last edited by MBensema; 03-26-2009 at 11:53 AM. Reason: clarified info

- Aluminum

- Join Date

- Dec 2007

- Location

- schoten belgium

- Posts

- 207

- Post Thanks / Like

- Likes (Given)

- 24

- Likes (Received)

- 27

about the din 2768 i think its a standart in europe over here

can give you a ling to the table with all the seizes but its a dutch chart but i cant look it up atm but basicly its

0-3mm +-0.05mm

3-6mm +-0.1mm

6-30mm +-0.15mm

and so forth

the h6 is for a schaft for example 25.4mm h6 would mean 25.4mm-25.387mm

if you pm me the seizes you want to know i can give you the dimensions in metric later this evening. - CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

MBensema,

Thank you for that link, it doesnt offer everything I need but it does come closer than I had gotten by myself.

I do have a shaft dimention that is not on the chart, it is for an OD 12mm h9. The chart skips over h9 for some reason. The other end of the shaft is 10mm h6 which should be +0,-.009 if I read the chart correctly.

Charles - CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

- Diamond

- Join Date

- Jun 2004

- Location

- Melbourne Australia

- Posts

- 5,456

- Post Thanks / Like

Charles

The chart skips over h9 for some reason.

h9 is in my version of the Machinery’s handbook (21st, page 1561)

Its telling me 11.957 / 12.000 It would pay to check that with one of the other members.

This link often gets put up with questions about ISO tolerance. That doesn’t include h9 either.

http://www.roymech.co.uk/Useful_Tables/ISO_Tolerances/ISO_LIMITS.htm

The same MHB, gives me a slight difference to your h6. It gives +0 / -0.011 or 11.989 / 12.000

Regards Phil. - CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

Machtool,

Yes I got that too, but there are a lot of other tolerances that are not listed in my handbook. I just need to find a better source and I am hoping to not have to buy all the standards if I dont have too. I am just quoting the job and I am still waiting on some answers from the company I got the drawings from. I thought I could get a head start and educate myself at the same time.

One shaft has a dim 25mm f9, a bore is marked M6 and to me that seems super tight, more than the part requires but I am hoping I just read the chart wrong. There are keyways and snap ring grooves and I just cant seem to find all the information I was hoping for in the MHB but I will keep searching.

Charles - Hot Rolled

- Join Date

- Sep 2002

- Location

- New Milford, CT

- Posts

- 565

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 4

Charles,

you have some weird tolerances on there, those are very rare for bearing fits.

I have an ISO Tolerance book my company published, but it looks like it is not available any longer.

12mm h9 +0 / -43

25mm f9 -20 / -72

10mm h6 +0 / -9

Is the M6 hole tolerance also 25mm? If so, it would be -4 / -17

By the way, DIN 2768mk is a general tolerance table that provides the tolerances for anything that is not toleranced on the drawing, it does not refer to the diameter tolerances you are asking about. You can find info on the DIN 2768 at the link below.

http://mdmetric.com/tech/DINISO1302extract.htm - CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

Thank you,

I just found the tolerances on the keyway, and no the M6 is on a 47mm bore which makes me wonder why so tight a tolerance, I was hoping I was reading it wrong. I didnt see where you got the -17 from, at least that would allow me to have a little more room to work.

On the 12mm my MHB must have a typo because it says the tolerance is +43 -0? I didnt think that correct for a shaft but that is what is in my book. Now you know why I wanted to ask others, this doesnt really add up.

I really do need some reference that I can point to for these just in case there is any problem I need some printed version of these tolerances. I will check out the general one you mentioned.

Charles - Hot Rolled

- Join Date

- Sep 2002

- Location

- New Milford, CT

- Posts

- 565

- Post Thanks / Like

- Likes (Given)

- 0

- Likes (Received)

- 4

bearing tolerances are usually fairly tight since that controls the amount of internal clearance of the rolling elements to the race of the bearing when installed.

An M6 tolerance on a 47mm bore should be -4 to -20 according to my book. I'm using a book published by FAG Bearings that lists the complete tolerance range for each designation, I don't have my Machinerys Handbook here to check and see what is in there.

The +43 on the h9 tolerance is definitely wrong, all the h tolerances are +0 and a negative number. Are you sure you are not looking at H tolerance tables? The capital H is for holes and all of those are 0 to a plus number.

After you have used it a bit, these tolerances get easier. I wish I had a copy of the complete tables I could email you, the following link is mounting and dismounting catalog that has tables in the back, but does not have all of what you are looking for.

http://www.schaeffler.com/remotemedi...00_3_de_en.pdf

If I find some time tomorrow, I will see if I can scan my tables and send them to you. - CBlairDiamond

- Join Date

- Sep 2002

- Location

- Lawrenceville GA USA

- Posts

- 6,177

- Post Thanks / Like

- Likes (Given)

- 706

- Likes (Received)

- 1320

Thank you all for your help, this has been quite an education so far but it does seem to follow a pattern and I am glad I have decided to follow up with it. Your help at least lets me know where I was right and where I need to work a little harder.

If anyone knows of a techical reference that might be more inclusive and useful I will gladly pay a little for the effort to copy and email or mail it to me. I was thinking of a Text book? Something some engineer in training might use or perhaps a machining student might have access to? I have several booklets on GDT and similar subjects but nothing on the european or DIN standards. Even if it was in German I could work with the tables or have one or two locals translate for me.

Thanks to all

Charles - Aluminum

- Join Date

- Dec 2007

- Location

- schoten belgium

- Posts

- 207

- Post Thanks / Like

- Likes (Given)

- 24

- Likes (Received)

- 27

http://www.vdwalle.com/knowledgebase/index.htm

the first one is for the shaft toleranties (normal letters)

the 2nd one is for borings capital letters

you can either download them or watch them online and its free

http://www.zyxtek.se/iso2768_eng.htm gives you a table with the tolerances

devided in 4 catagories

f= finework

m= mediuml work and this is the one you need to see since you need the iso 2768 mk

c= course work

v= very course work - mraineyStainless

- Join Date

- Jul 2004

- Location

- Spartanburg, South Carolina

- Posts

- 1,518

- Post Thanks / Like

- Likes (Given)

- 49

- Likes (Received)

- 98

Being a software junkie, I'll mention the program 'Tolerances and Fits', which sells for 20 Euros (~$26.50). I haven't used it, but the demo looks interesting.

http://www.qsyst.com/qualisyst_en.htm

- Site Areas

- Forums

- Manufacturing Today

- Specific Machine Forums

- Open Discussion

- Commerce

- Machinery Manual, Brochure and Photo Archives

- Forum features

Iso 2768 Hole Tolerances

Bookmarks

Posting Permissions

Iso 8015 Tolerancing

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

Din Iso 2768 Mk Tolerance

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off